On June 17, the 100KG waste plastic pyrolysis plant ordered by the customer in Rio, Brazil from DOING Factory has been delivered to Rio, Brazil.

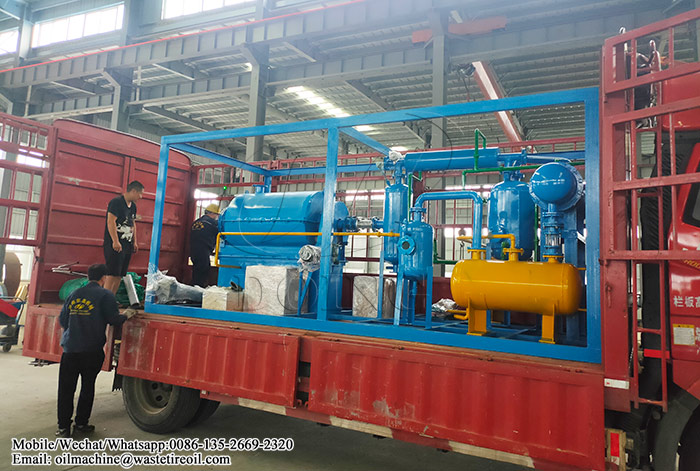

waste plastic pyrolysis plant packed in DOING Factory

waste plastic pyrolysis plant packed in DOING Factory

The customer runs a plastic recycling company, so there is a large amount of raw materials to deal with. The customer had purchased a set of waste plastic pyrolysis plant from other factories previously, but the cooling effect was not very good, so he wanted to change another set of equipment. After our project manager introduced our equipment to the customer, the customer felt that our equipment was very good and was satisfied with the cooling system. Therefore, the customer firstly ordered a 100KG waste plastic pyrolysis plant to see the effect, and then buy the continuous waste plastic pyrolysis plant.

waste plastic pyrolysis plant packed in DOING Factory

waste plastic pyrolysis plant packed in DOING Factory

waste plastic pyrolysis plant packed in DOING Factory

waste plastic pyrolysis plant packed in DOING Factory

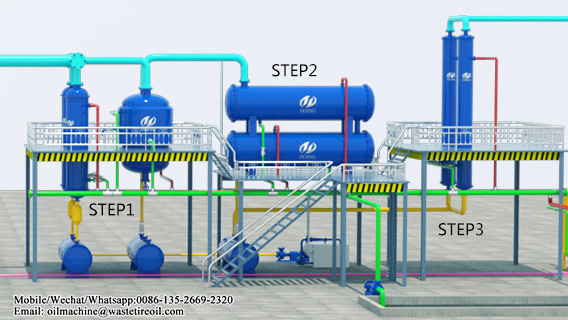

Doing Group waste plastic pyrolysis plant adopts the three-step cooling system, including 2 vertical condensers, 2 horizontal condensers and 2 condensation towers. The cooling area is 1.5 times that of oil gas, the heat exchange area is large, thus to get fully cooling effect.

Cooling system

Cooling system

After a period of time, the customer will receive the equipment, and our engineers will assist the customer to install the equipment. If you want to know more information about waste plastic pyrolysis plant, welcome to consult us.